Fabrication

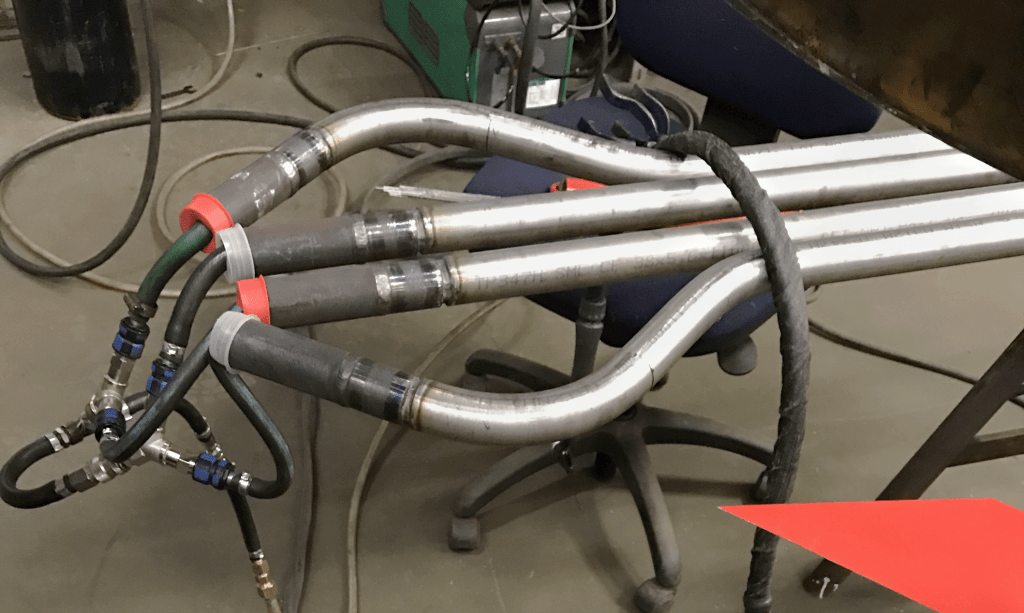

C-DSH - DSH

Did you know we can fabricate control desuperheaters (C-DSH) and desuperheaters (DSH) at our workshop? Our experienced engineers also inspect, repair and replace units on main boilers.

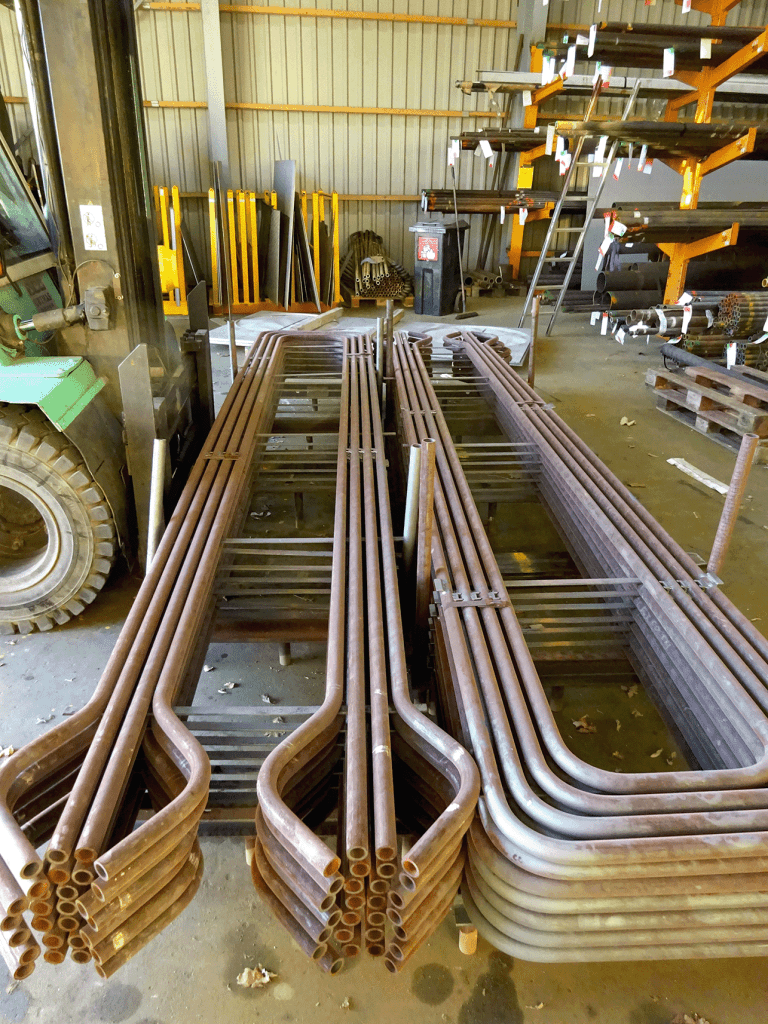

Superheater

Our experienced boiler specialists fabricate superheater tubes at our workshop and can accept special fabrication requests to fit your boiler needs. We also inspect, repair and replace.

New Boiler

Want to go greener by installing WHR boilers, replace the boiler due to extensive damage or do you just want to change boiler type? We’re ready to help with the fabrication of a new boiler!

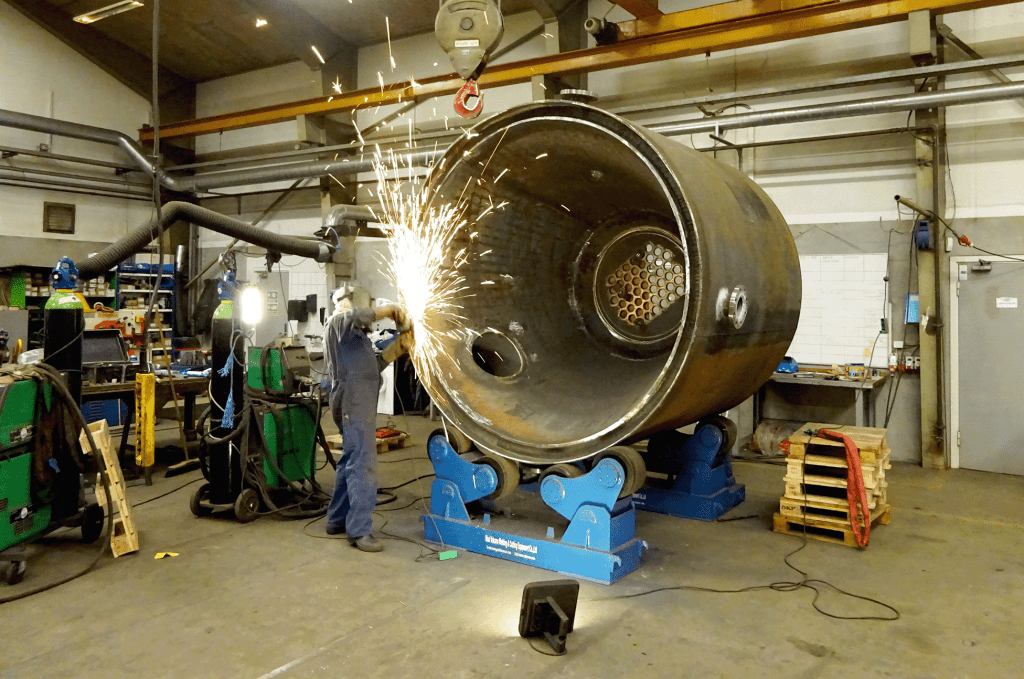

Waste Heat Recovery

Want to have the benefits of waste heat recovery? We offer fabrication to help you reach short ROI time and become eco-friendlier. Both for new installations and retrofit!

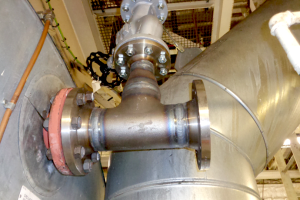

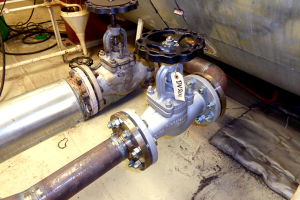

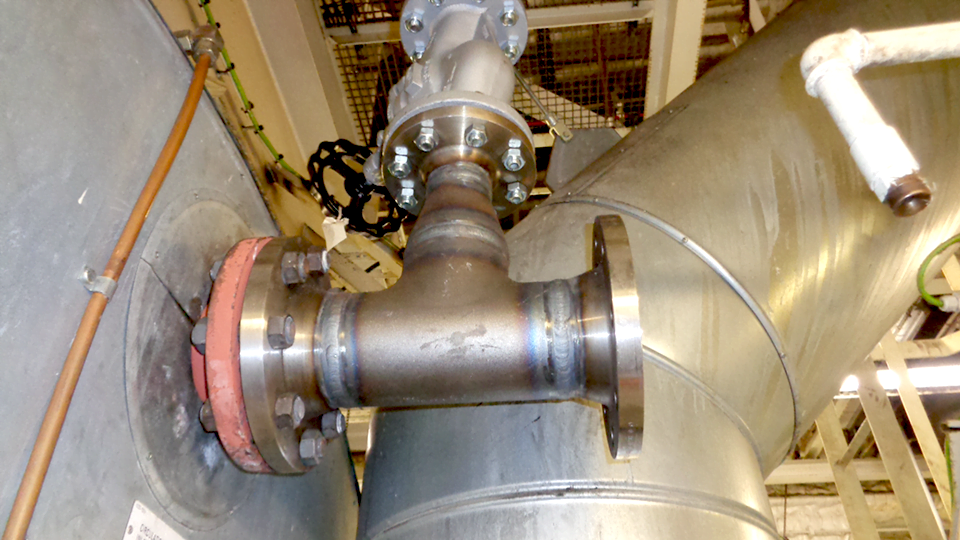

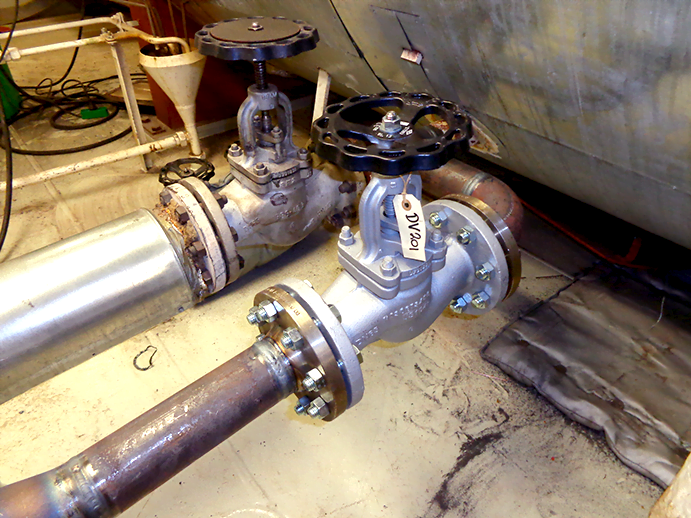

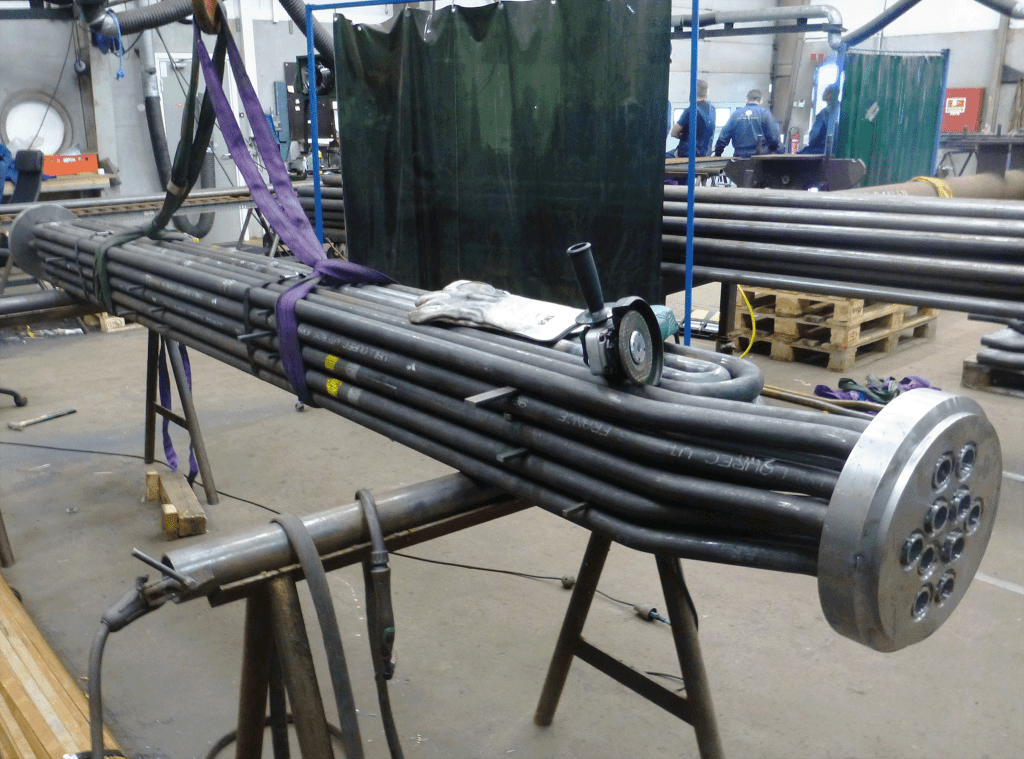

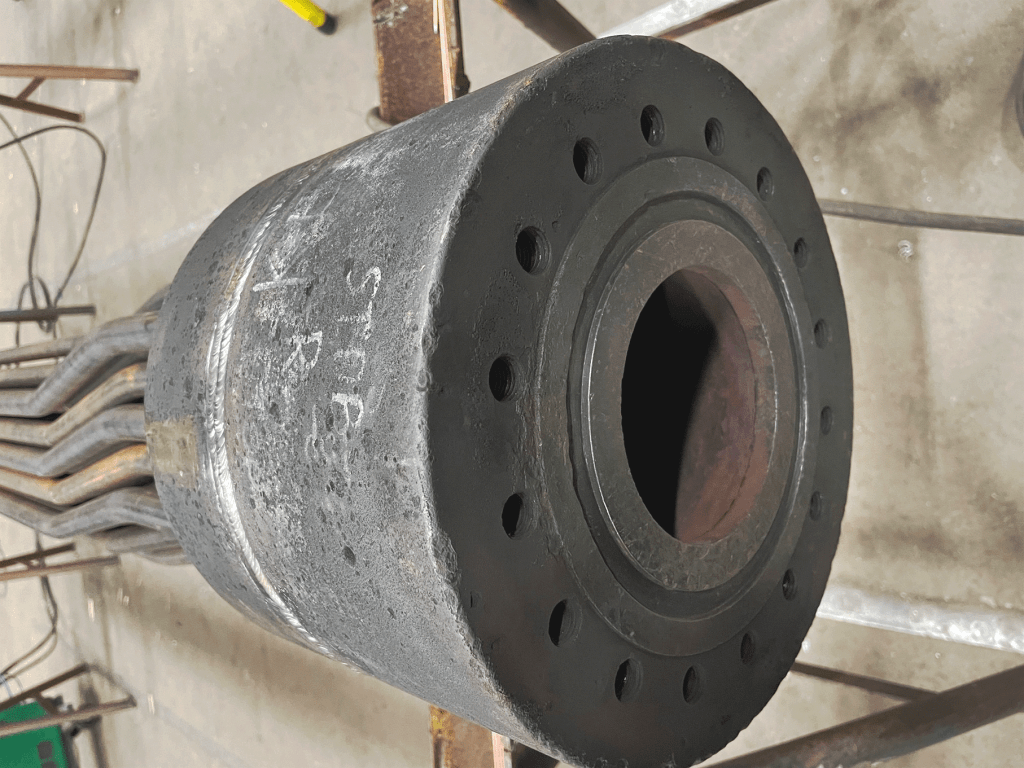

CDSH - DSH

Global Boiler Aalborg is able to fabricate control desuperheaters (C-DSH) and desuperheaters (DSH) for main boilers. At our workshops, we can fabricate both types (C-DSH and DSH) in both a flanged or a welded version. For the shipping, we prepare them for installation onboard your vessel.

Maintaining your Desuperheater/ Control Desuperheater is crucial to ensure efficient and safe operation of your main boiler. And we have many years of experience in inspecting, repairing, fabricating and replacing Desuperheater/Control Desuperheater units on main boilers.

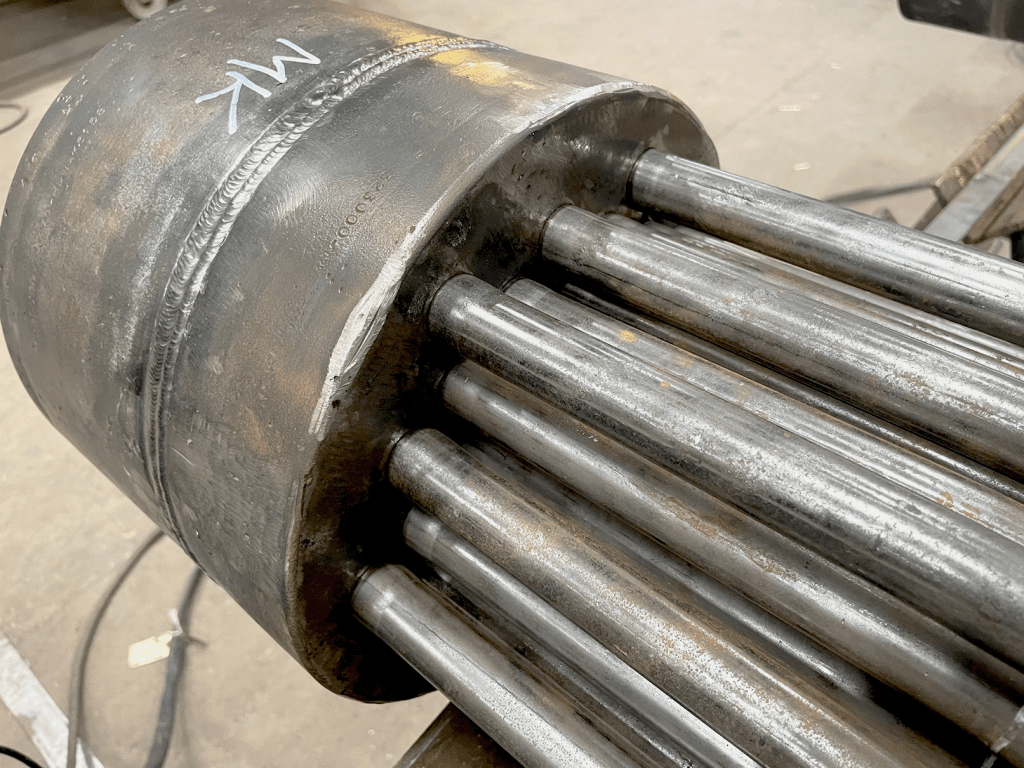

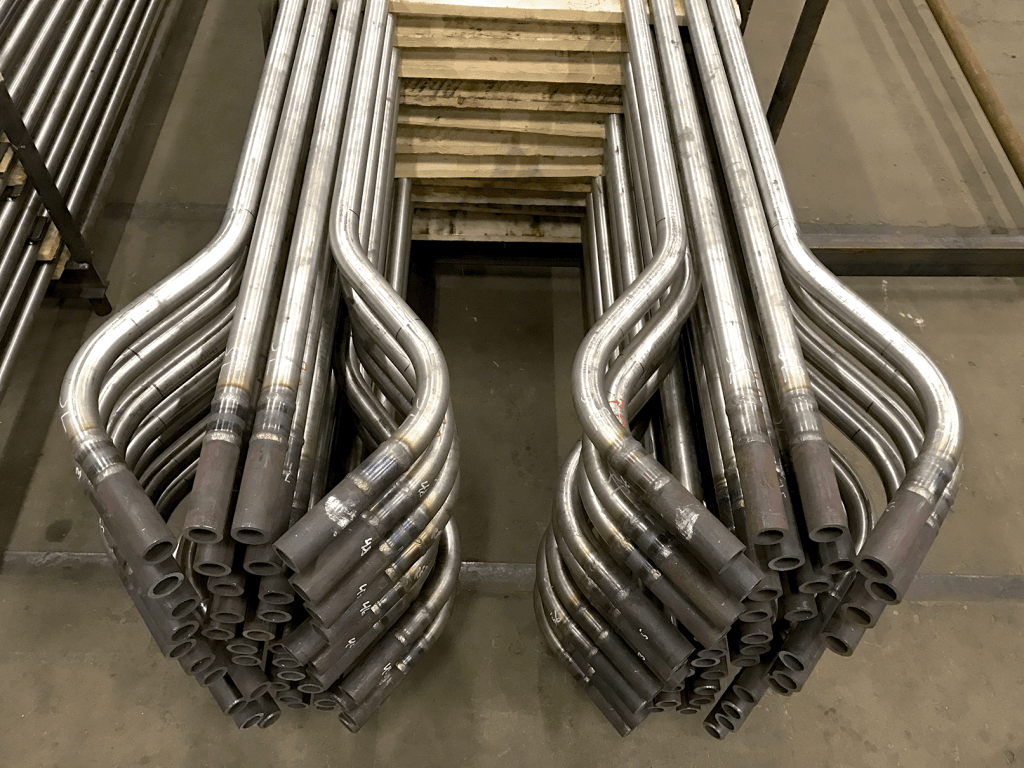

Superheater

Maintenance and repair of the marine boiler super heater tubes are crucial for several reasons:

Efficiency:

The performance of the super heater tubes can directly impact the efficiency of the vessel’s power generation system. If the tubes become corroded, fouled, or damaged, the system may not operate at peak efficiency. This leads to higher fuel consumption and increased operating costs.

Reliability:

Super heater tubes are subjected to high temperatures, pressures, and corrosive environments, which can cause wear and tear over time. Regular maintenance and repair can help ensure the tubes are in good condition and can perform reliably. This is reducing the likelihood of unexpected downtime and associated costs.

Overall, the maintenance and repair of the marine boiler super heater tubes is crucial to ensure the safety, efficiency, reliability, and regulatory compliance of a vessel’s power generation system. Regular inspection and maintenance of the super heater tubes can help detect issues early and prevent costly repairs or downtime.

Therefore, we also provide inspection, repair, fabrication and replacement of your superheater tubes. In that way, we can help you keep an efficient and reliable operation of your boilers.

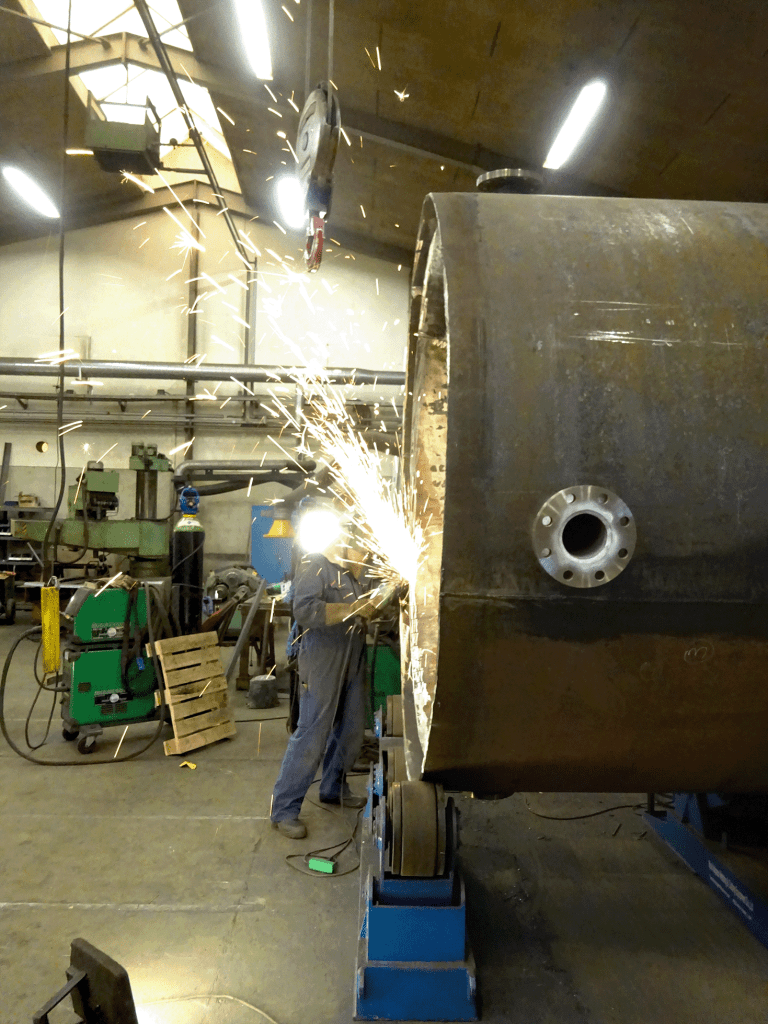

New Boiler

Are you looking to upgrade your green profile? This can be done by installing WHR boilers, replacing your boiler or economizer due to extensive damage or maybe deciding to change your boiler type. For this, we are always ready to help you in the process of going greener.

And with our experienced boiler specialists, we will guide you from the very beginning. From the initial contact, inspection onboard, design process, fabrication, and installation of your new Boiler/Economizer/WHR unit. And if you have any special requests we will always be ready to be your sparing partner to ensure you are wellinformed on your new project.

We are always ready to help you on your decision. Be it to change the boiler type, replace your boiler or economizer due to extensive damage, or upgrade your green profile by installing Waste Heat Recovery boilers. Then we are ready to assist.

Waste Heat Recovery

For new installations or retrofit, an efficient exhaust gas economizer utilizing the heat in the exhaust gas from the auxiliary engines during port stays will significantly reduce the oil consumption for the oil-fired boiler.

Waste heat recovery from engines can have various benefits: the heat rejection to exhaust requires 50% of the total consumed energy, but an economiser may recover up to 40% of this energy. This results in a short ROI time and makes the vessel eco-friendlier.