Marine boiler upgrades and redesign

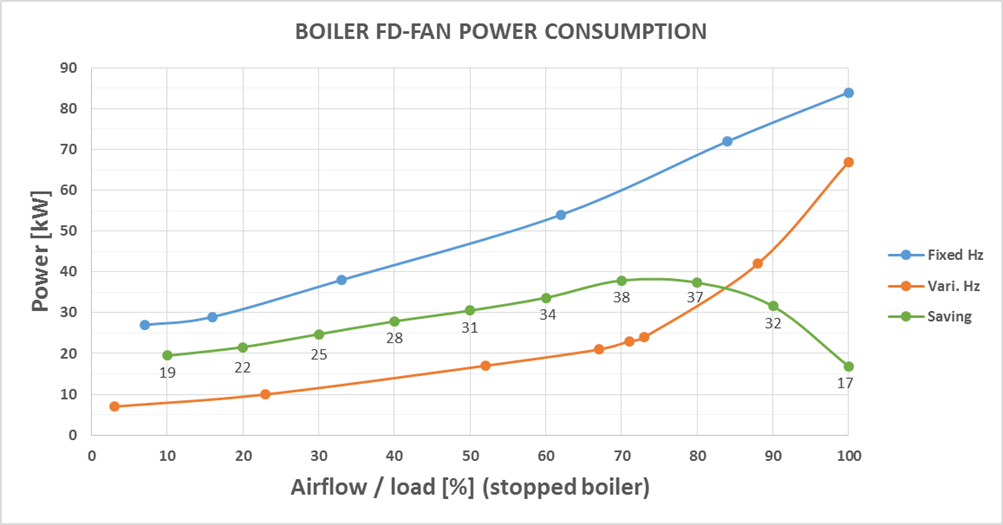

AC Drive

Want to reduce the required minimum load of stem demand? What about installing an AC drive and get up to 75% cost reduction of running your boiler in low steam-demanding situations.

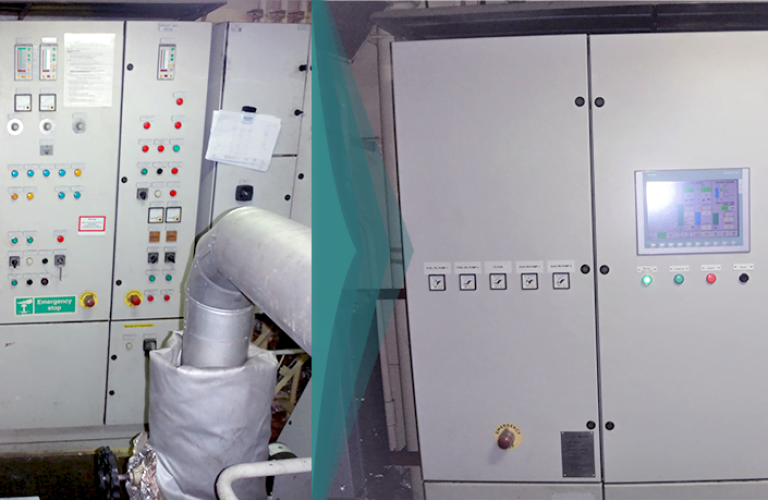

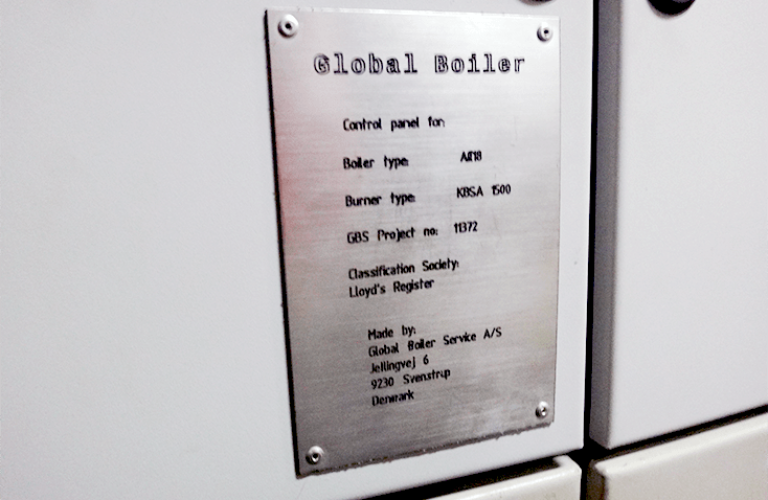

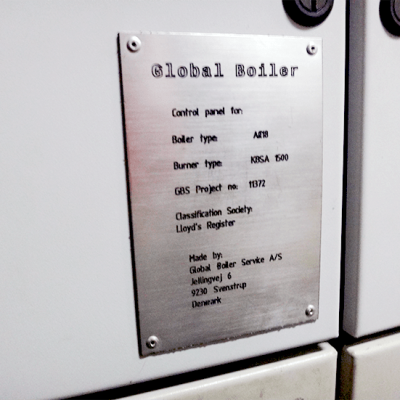

Complete Boiler Control System

With a control system from Global Boiler Aalborg you ensure a safe and reliable operation with minimum attendance. Get a costume fit for your vessel.

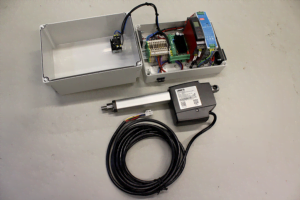

Linear Actuator

With a linear actuator you’ll get precise and steady damper control. Should you need your pneumatic linear actuators replaced with new fully electrical actuators, we are ready to assist you.

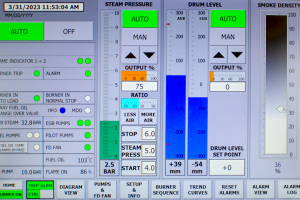

PID

Out to save on time spent on the day-to-day maintenance of your boiler? A PID helps you achieve that and controls several control operations in one place.

AC Drive

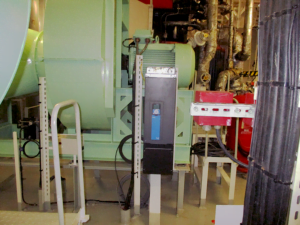

The AC drive is an optional installation applicable to burner systems with separate FD fans e.g. steam atomising burner etc.

In many cases, the size of the boiler plant on tankers is based on cargo-handling situations with very high steam demand. However, while at voyage the steam demand for your vessel is highly reduced. For most marine boiler plants, the minimum load is approximately 20% of the full steam capacity which often is much higher than actual steam demand during sea voyage.

By installing an AC drive it is possible for you to reduce the required minimum load of your burner even further, and still keep the boiler active, and thus avoiding start/stop cycles of your boiler.

The AC drive from Global Boiler Aalborg can in some instances reduce the minimum load to approximately 5-7% of the boilers steam capacity. This results in up to 75% cost reduction of running your boiler in low steam-demanding situations.

Using AC drives to control the speed of the combustion air fans can result in several benefits, including:

- Improved energy efficiency: By adjusting the air supply to match the demands of the boiler, AC drives can reduce energy consumption and improve the overall efficiency of the system.

- Reduced wear and tear: By controlling the speed of the fans, AC drives can reduce the wear and tear on the equipment, resulting in longer service life and lower maintenance costs.

- Improved safety: By ensuring proper combustion and preventing excess air from entering the furnace, AC drives can help prevent fires and explosions in the boiler.

Complete Boiler Control System

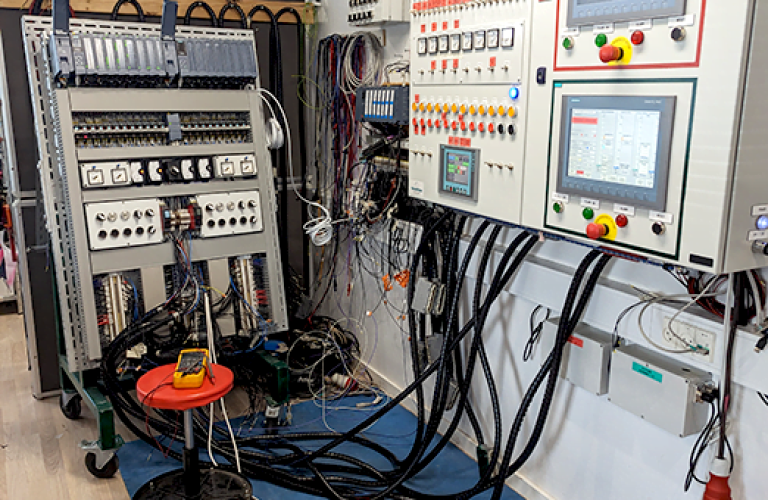

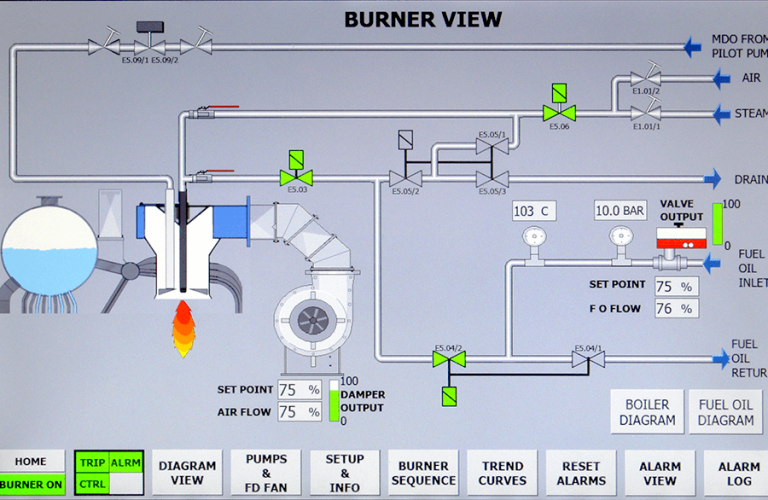

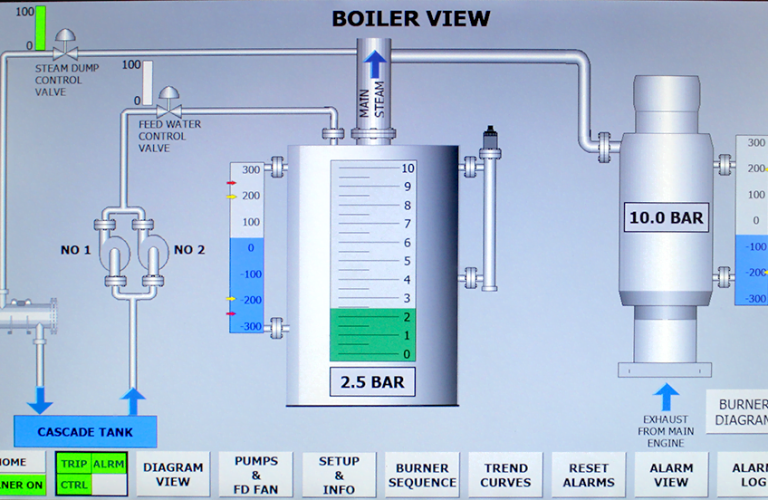

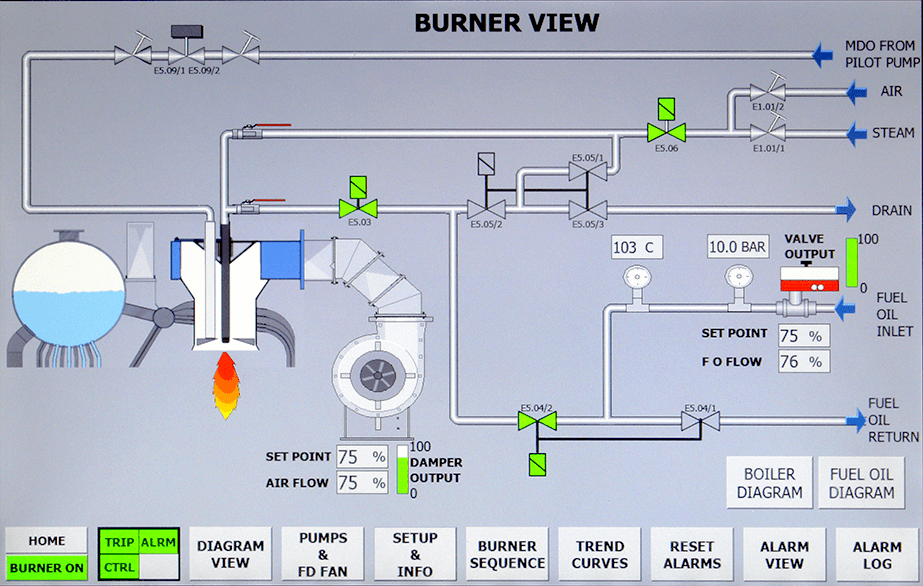

The control systems for your boiler provided by Global Boiler Aalborg are all engineered to ensure safe and reliable operation with minimum attendance. This is achieved through the use of high-quality components and an easy-to-use user interface.

The PLC at the base for the system is the Siemens S7-1500, which is a well-tested and highly reliable PLC with components available world wide.

The system is able to be implemented in a single-boiler system or in a multiple-boiler system. This is regardless of whether it’s a new build control system or a marine boiler control system retrofit. This kind of service is available to any kind of boiler and burner.

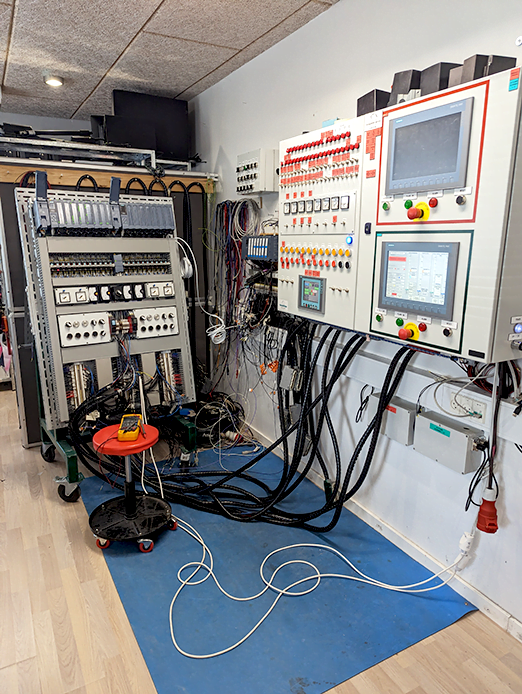

Before shipping and installing the system on your vessel, our automation engineers have made thorough tests on the full control system and conducted FAT with Class to ensure everything is working as intended.

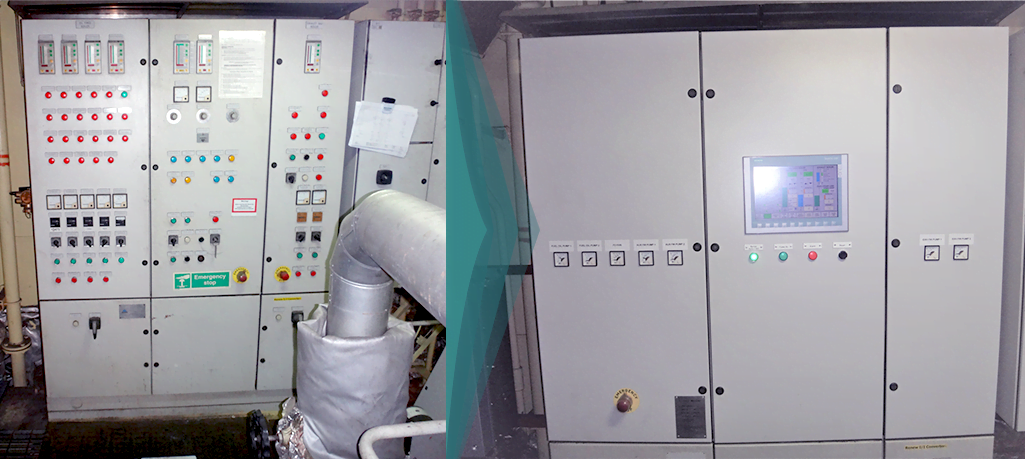

Please look at the before and after photos to your right for reference.

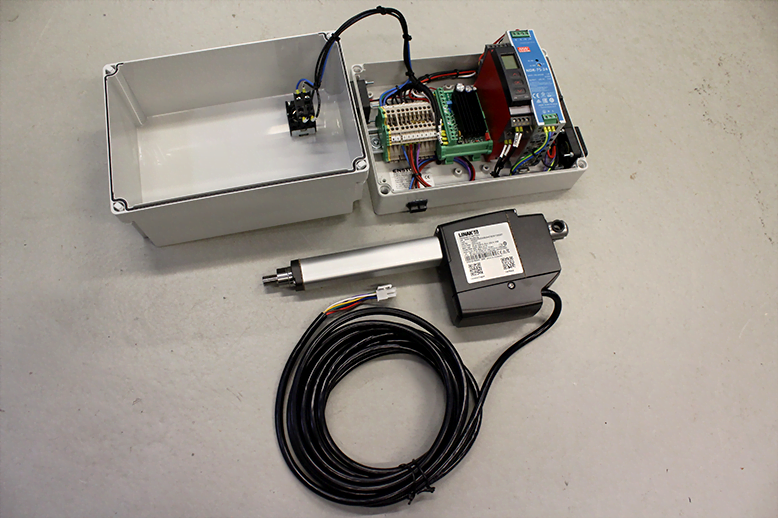

Linear Actuator

Electrical actuators are preferable because they provide a more accurate setting and requires less maintenance compared to the pneumatic systems. Therefore, these are perfect for optimizing your FD fan’s positioning or bypass damper. Should you need your pneumatic linear actuators replaced with new fully electrical actuators, then we are ready to assist you.

All our actuators are fully compliant with the marine industry, as they come with a robust design and are simple to install as a plug-and-play solution with built-in limit switches and a pre-assembled control box.

Linear actuator for precise and smooth damper control.

Marine boiler retrofit to existing plants:

- Various plug-and-play solutions available

- Built-in limit switches

- Low maintenance

PID

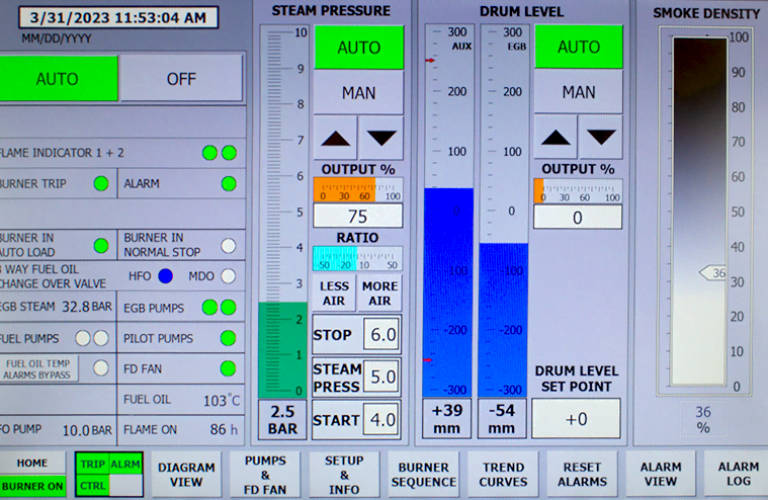

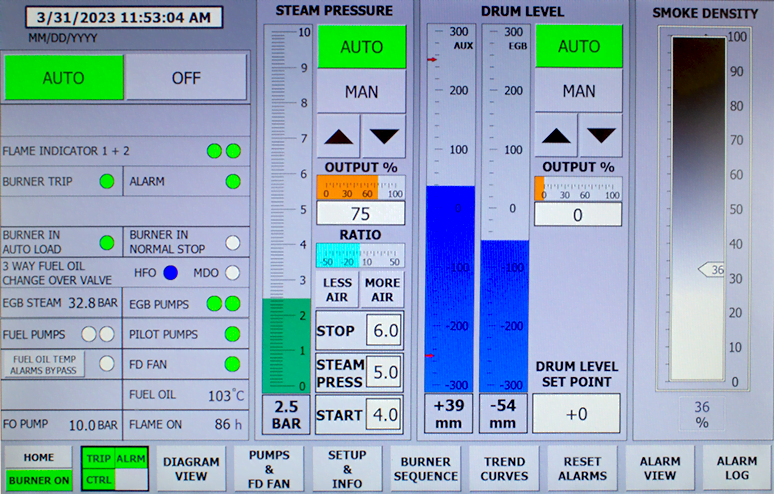

If you want to save time in your day to day maintenance of your boiler, a PID controller might be what you need. With a PID controller from Global Boiler Aalborg, it is possible to integrate several controllers into one system.

With the Siemens S7-1200 CPU as its core, it ensures an easy-to-use User Interface via HMI with the possibility of future expansions of control loops within your boiler configuration.

A PLC-based PID controller can function as one system to replace several controllers. Instead of requiring several controllers, the PID controller can be integrated and can provide several control operations on its own, e.g. oil/air, water level, steam pressure, etc.

With the Siemens S7-1200 CPU as its core, it ensures an easy-to-use Human-Machine-Interface (HMI) with the possibility of future expansions of control loops within your boiler configuration.