Repair jobs

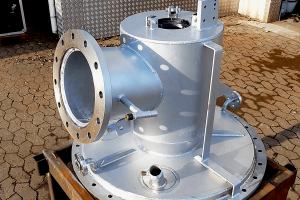

Thermal Fuel Oil

Global Boiler Aalborg builds on a long well-reputed background in the industry and have more than 20 years individual background for construction and repair of boilers.

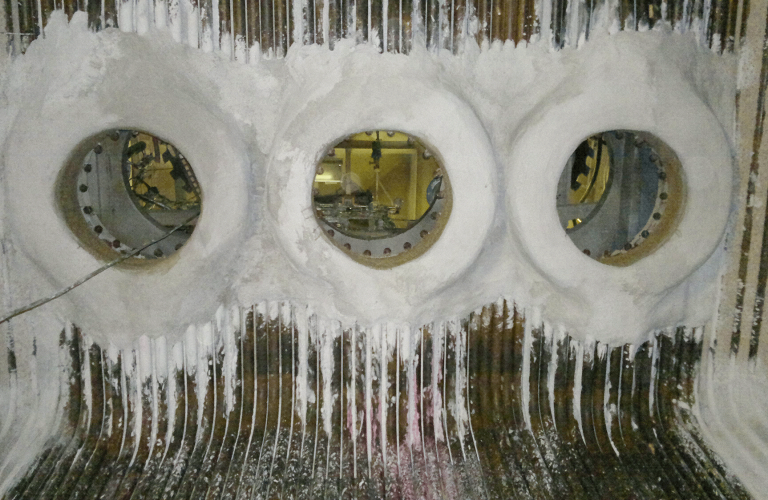

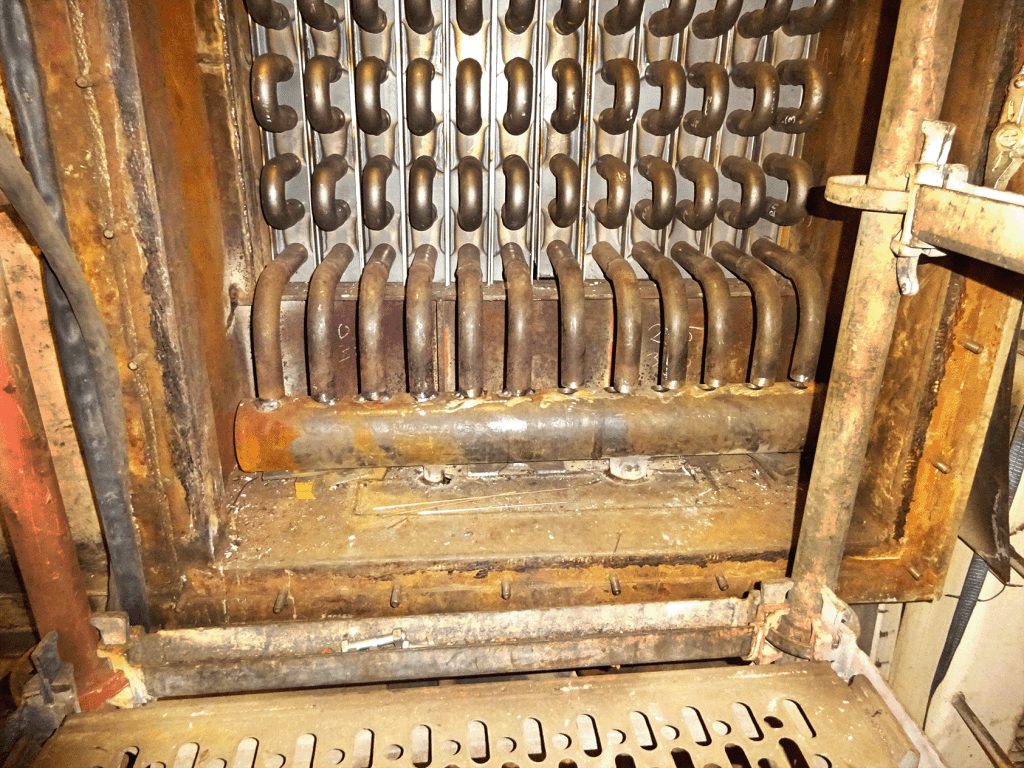

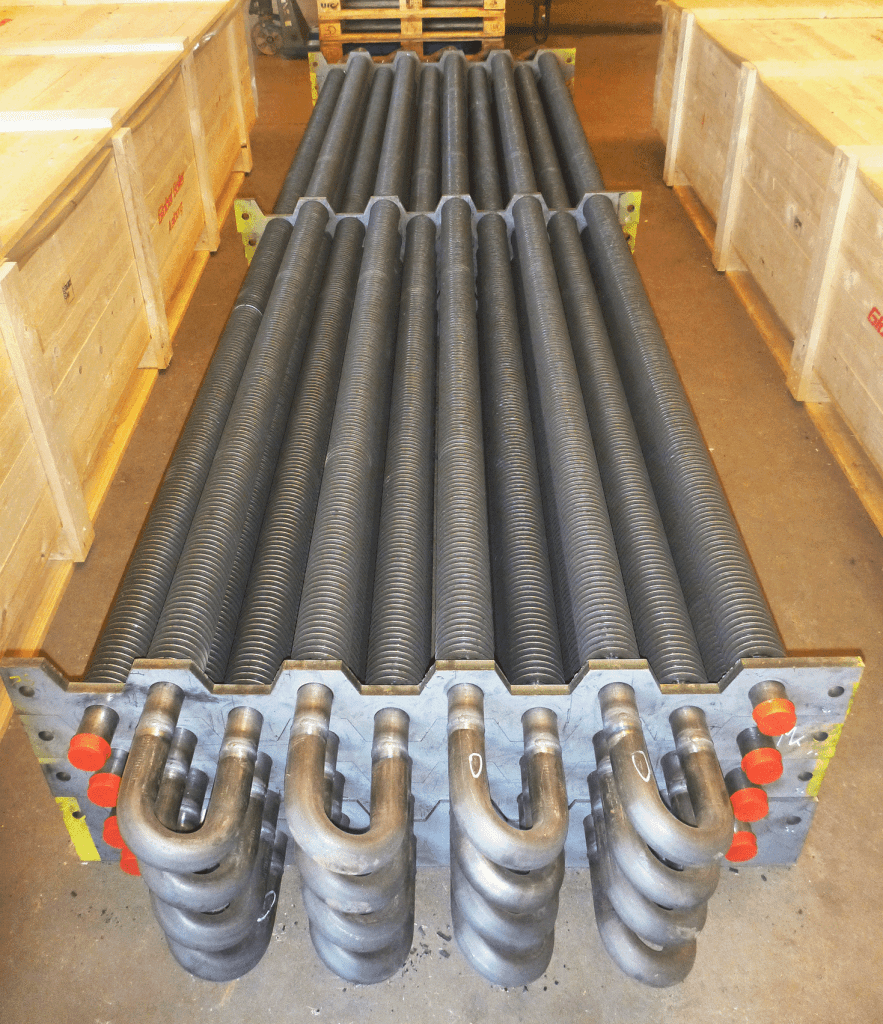

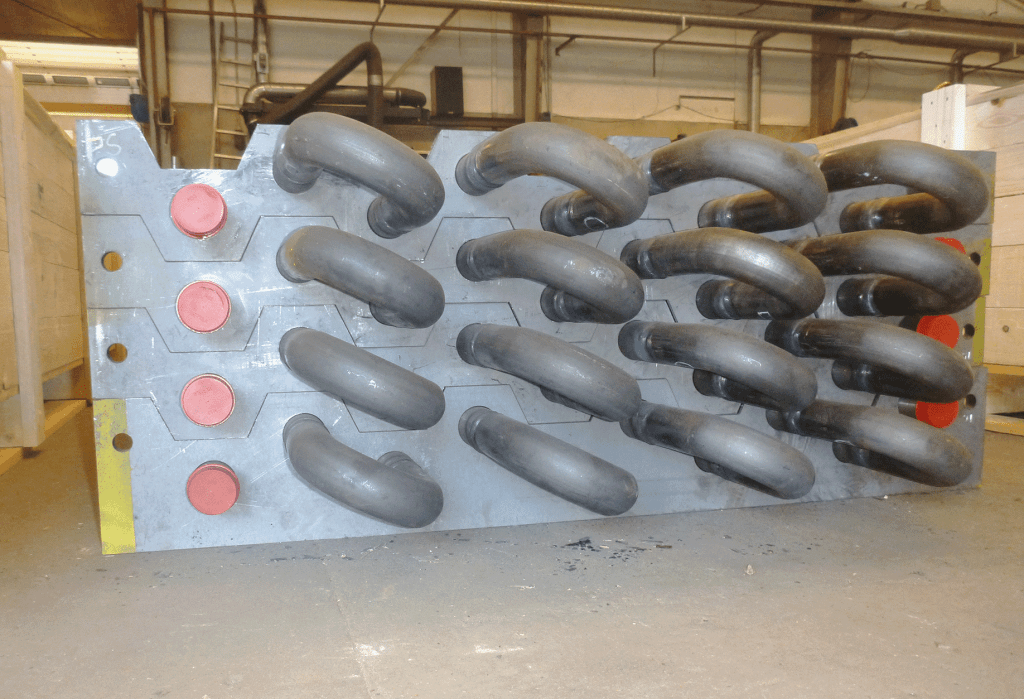

Economizer

We manufacture various types of tube sections – be it H-finned, double H-finned, spiral-finned or older tube types, we are class certified regardless of type.

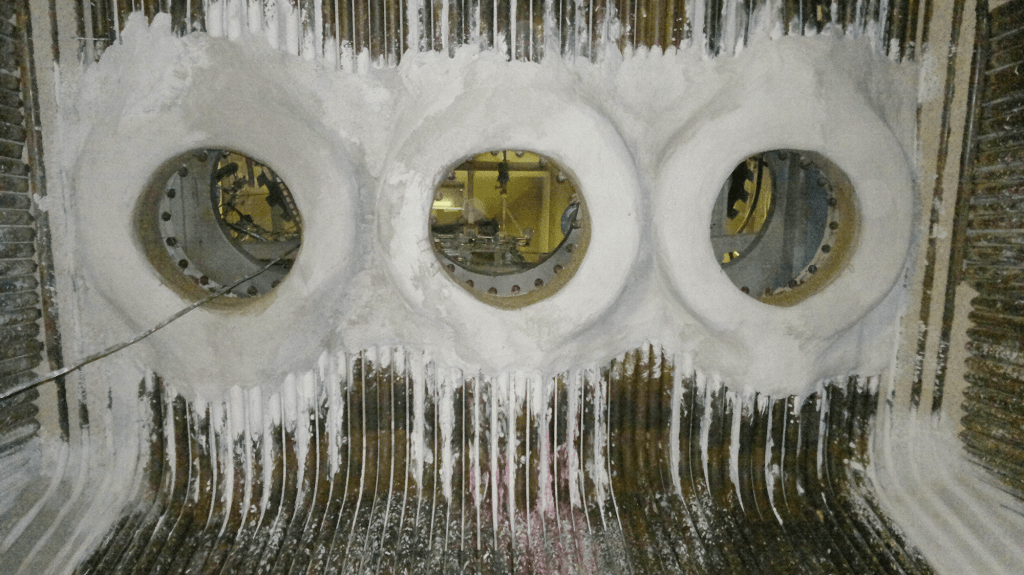

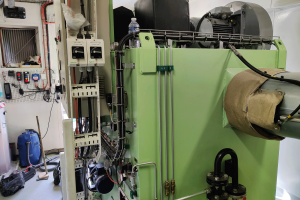

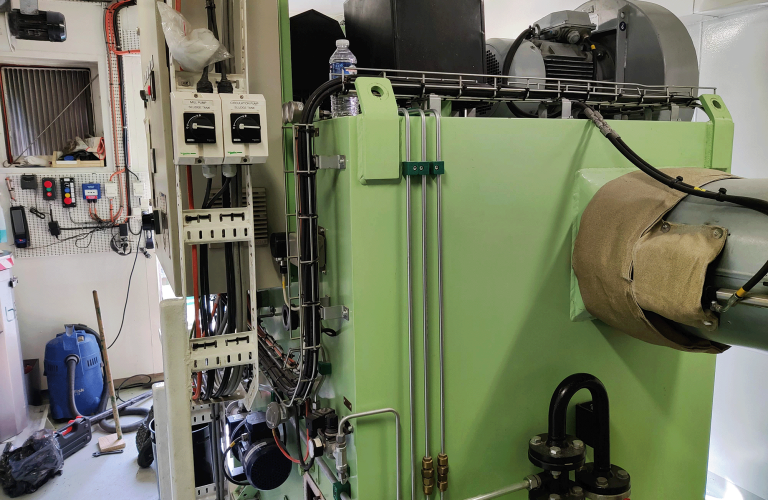

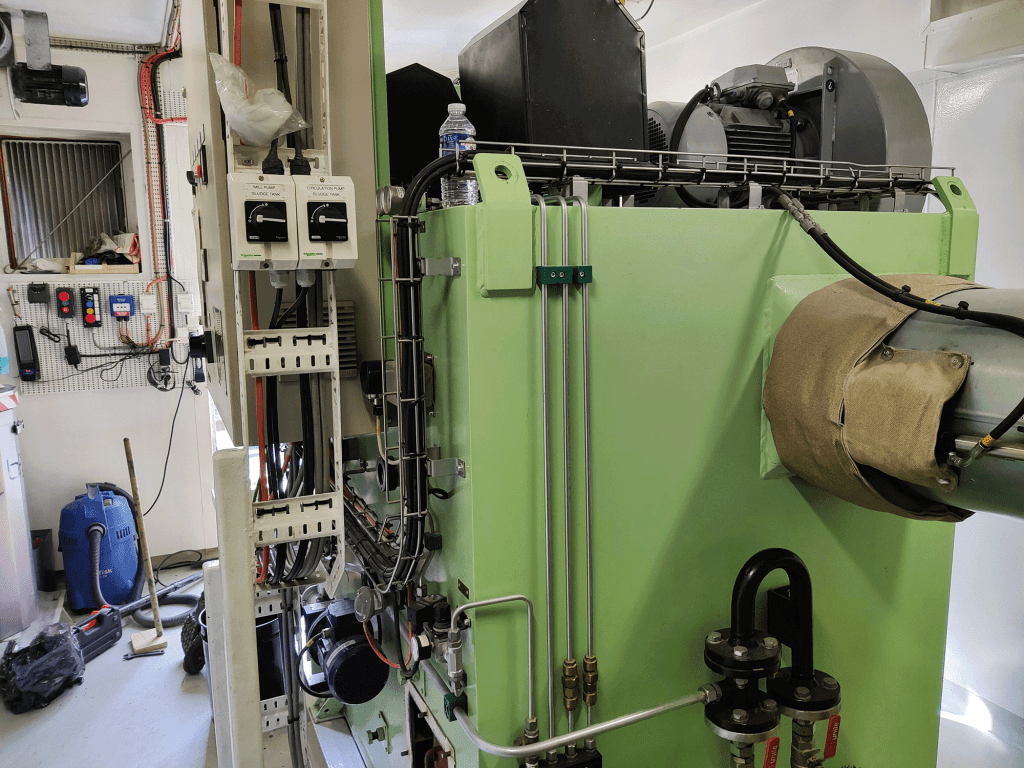

Inert Gas Generator

We offer worldwide services and repair technicians for your IGG plant – to ensure continuous and safe operating conditions.

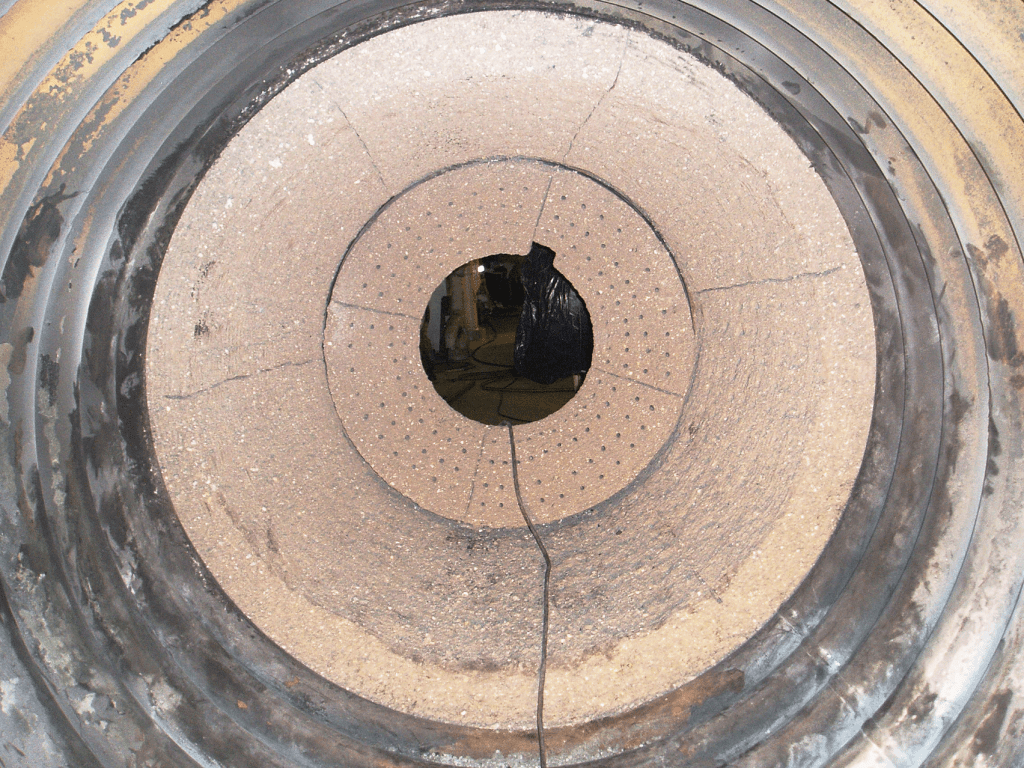

Incinerator

Is your incinerator in bad shape? Our experienced engineers are ready to help you get it in the best possible condition, no matter the brand.

Refractory Repair & Replacement

Want to avoid boiler shutdown? We offer heat-resistant boiler refractory that helps prevent thermal loss during operation.

Thermal Fuel Oil

Global Boiler Aalborg is your highly qualified one-stop dedicated supplier for repair for any kinds of boilers — whether it’s a small “donkey” boiler on a cargo vessel, a larger “cargo” boiler on a tanker vessel, or the ultimate “main boiler” on a steam propulsion vessel.

At Global Boiler, we understand the critical role that TFO (Thermal Fluid Oil) boilers play in the maritime industry. These boilers are vital for maintaining optimal temperature conditions and ensuring the smooth operation of various onboard systems. With our expertise and extensive experience, we offer comprehensive service and repair solutions tailored to meet your specific needs.

Our highly skilled team of technicians possesses in-depth knowledge of TFO boilers and the intricacies involved in their maintenance and repair. We utilize our knowledge to diagnose, troubleshoot, and resolve any issues promptly.

Whether you require routine maintenance, emergency repairs, or system upgrades, we are dedicated to delivering top-notch services that minimize downtime and maximize efficiency.

Trust Global Boiler Aalborg to be your trusted partner for all your TFO boiler service and repair needs. Contact us today to learn more about how we can optimize your boiler systems and keep your vessels sailing smoothly.

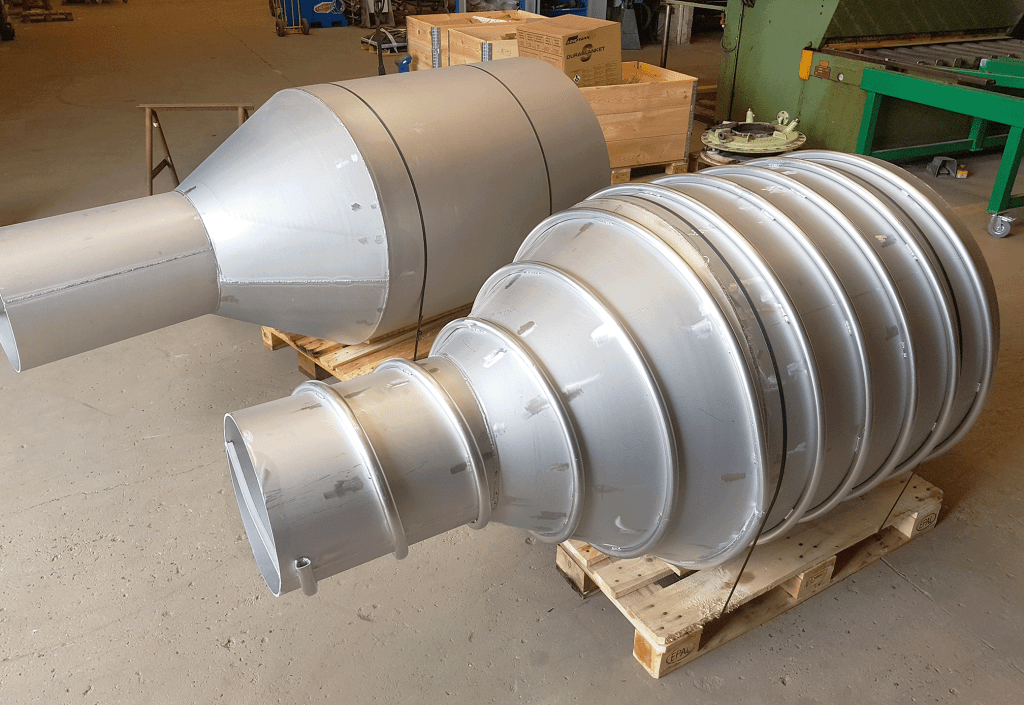

Economizer

Global Boiler Aalborg has extensive experience in designing and manufacturing various types of tube sections for the major OEM economizers. We can supply most types of finned economizer tubes: single “H”-finned, double “H”-finned, and spiral-finned.

Older types of coiled plain tube economizers such as the La Mont and Clayton types can also be supplied to customer-specific dimensions.

Global Boiler Aalborg builds on a long and well-reputed background in the industry. All of our key service employees have more than 20 years of individual background in construction, manufacture and repairs of boilers.

By choosing Global Boiler Aalborg, you are ensured that all repairs are Class certified regardless of the type of tubes needed, finned or coiled.

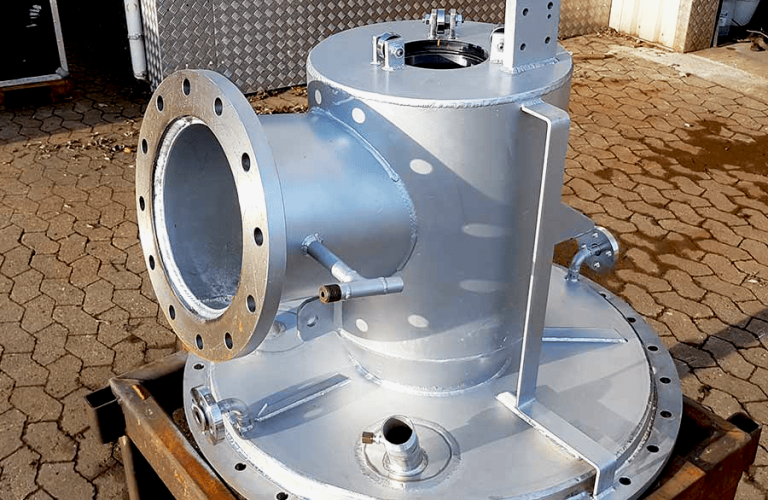

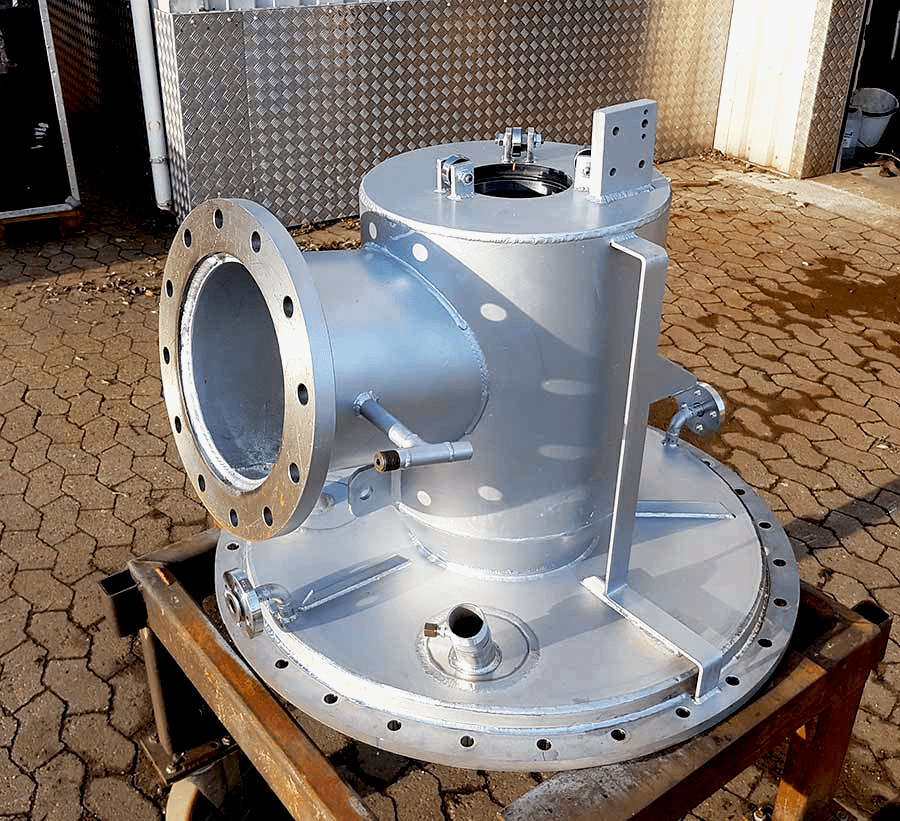

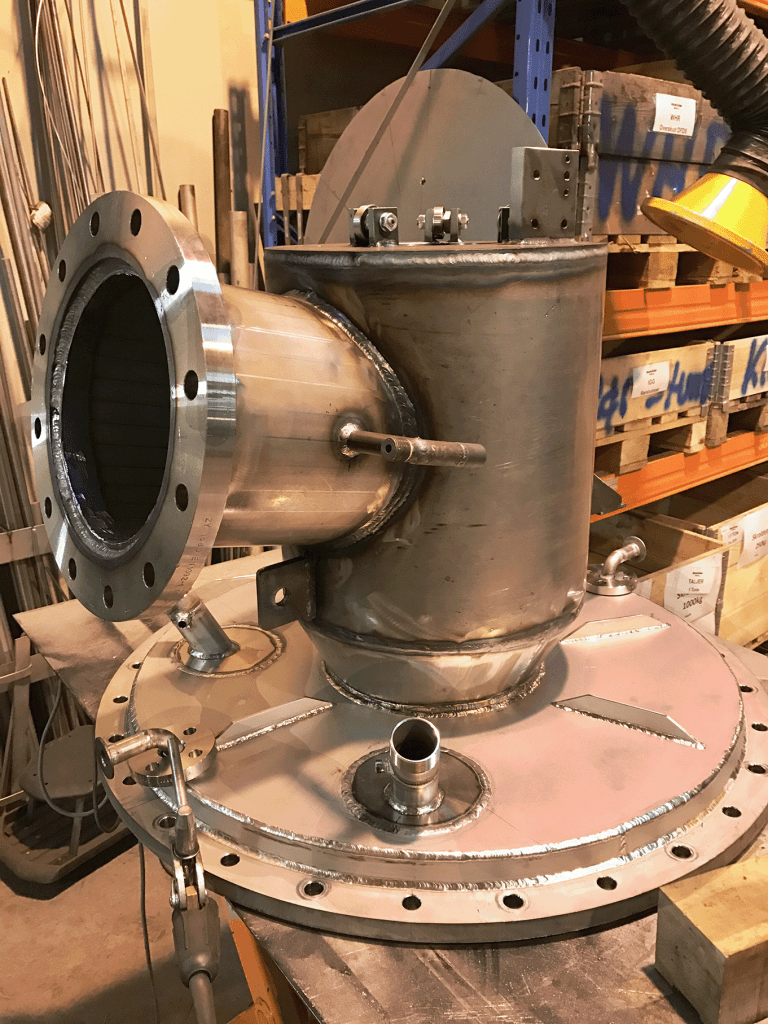

Inert Gas Generator

Your Inert Gas Generator is one of the most integral parts of maintaining safe operation of your vessel.

At Global Boiler Aalborg our service and repair technicians are available worldwide. We are always ready to carry out service and repair to your IGG plant, to ensure continuous and safe operating conditions. We can manufacture almost any parts for you IGG plant at all our departments within short notice. So no matter where in the world your vessel is located, we are ready to help.

Our experienced specialists are ready to help you no matter what type or brand of IGG plant you require help with. Additionally, we are able to manufacture most parts for your IGG plant within short notice.

Incinerator

It is important to have your incinerator running in good condition in order to ensure efficient steam production of your boiler. No matter what condition your incinerator is in, our experienced engineers are ready to help get your incinerator up and running in the best possible condition.

The scope of the job does not matter as we can conduct both refractory renewal and replacement of your incinerator. We repair all brands of incinerators, so it does not matter whether you have popular brands such as KangRim, Hyundai, Atlas, Hamworthy Moss, etc., or any other type of incinerator. We will do the job.

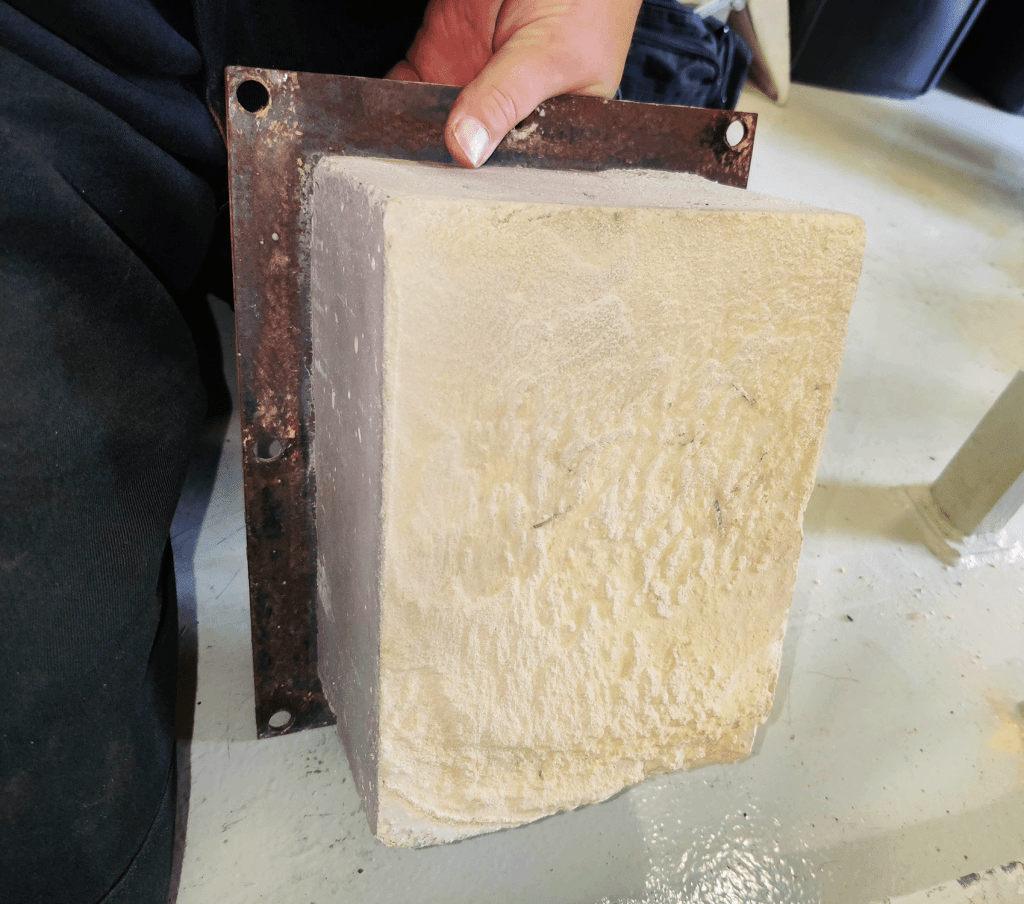

Refractory Repair & Replacement

Boiler refractory issues are one of the leading causes of boiler shutdown and also one of the easiest to go undetected.

The boiler refractory is heat resistant materials that are used to line the crucial parts of the boiler internal and to help prevent thermal loss during operation by retaining the heat.

What causes refractory damage?

While refractory tends to be resilient in nature, it is considered a consumable, where the regular normal use of your boiler plant/Incinerator will cause wear and tear over time. This is caused by high temperatures, pressure, slag and boiler fuel chemicals.

One of the most common causes of refractory failure, outside general wear and tear, is spalling. This is when the refractory materials expand or contract at different rates due to thermal conditions. This often results in cracks in the refractory that require repair.

Finally, if the incorrect refractory materials are installed, it will eventually lead to failure. When this occurs, the refractory is often unable to handle the pressure or heat and begins to crack or crumble.

Finally a good rule of thumb is that if the crack or missing piece of refractory is larger than your fist, you should contact us and have one of our refractory specialists help you out by repairing or replacing the damaged part.

Boiler refractory issues are some of the leading causes of boiler shutdown and can easily go undetected. The boiler refractory is made of heat-resistant material which are used to line the crucial parts of the boiler internals and to help prevent thermal loss during operation by retaining the heat.

What causes refractory damage?

Though refractory is considered resilient by nature, it’s still considered a consumable; normal use of your boiler plant will cause wear and tear over time due to the high temperatures, pressure, slag and boiler fuel chemicals.

Besides wear and tear, one of the most common causes of refractory damage is spalling where the refractory material has expanded or contracted at different rates due to thermal conditions, thereby resulting in the refractory cracking and/or crumbling.

A good rule of thumb regarding the refractory in your boiler plant is that if the crack or missing piece is larger than your fist, it is highly advised to get it repaired or replaced.

Should the need arise, our refractory specialists are ready to help examine your refractory and help with the repair or replacement of the damaged part.